How to control the quality of PCBA assembly processing?

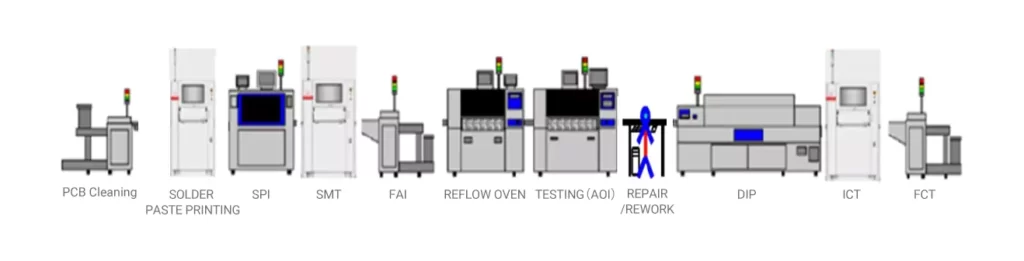

The PCBA assembly and processing process involves many links. If you want to produce high-quality PCBA products, the quality of each link must be controlled. PCBA products consist of processes such as PCB manufacturing, component procurement and inspection, SMT patching, plug-in processing, program burning, and testing. Next, New Reach will introduce you to the quality control points of PCBA assembly and proofing processing.

1. PCB circuit board manufacturing

Before the PCBA board is produced, the Gerber file must be analyzed, paying attention to the relationship between the PCB hole spacing and the board’s load-bearing capacity, not causing bending or breakage, and whether high-frequency signal interference, impedance and other key factors are considered for wiring.

2. Component procurement and inspection

The procurement of components requires strict channel control, purchasing from large merchants and original manufacturers, and 100% eliminating second-hand materials and counterfeit materials. Establish special incoming material inspection personnel to strictly check the functions of components to ensure that there are no defects in the components.

3. SMT patch processing

Solder paste printing and reflow oven temperature control are key to SMT chip processing. Reflow oven temperature and speed control are crucial to solder paste infiltration and soldering reliability, and can be controlled according to normal SOP operating guidelines. AOI testing must be strictly implemented to minimize the adverse effects caused by human factors.

4. DIP plug-in processing

In the DIP insertion process, wave soldering mold design is the key. How to use molds to maximize the supply of good products after the furnace is a process that PE engineers must constantly practice and sum up experience.

5. Program burning

In order to enable the PCB circuit board to achieve specific functions, you need to add software, and you need to “burn” the program. Before starting the “burning”, we need to test whether the PCB board is qualified, and then choose the appropriate burning method. . Current burning methods are generally divided into offline burning and online burning.

6. PCBA board testing

The main test content of PCBA testing includes ICT circuit testing, FCT functional testing, aging testing, temperature and humidity testing, drop testing, etc., and operates according to the customer’s testing plan and summarizes the report data.